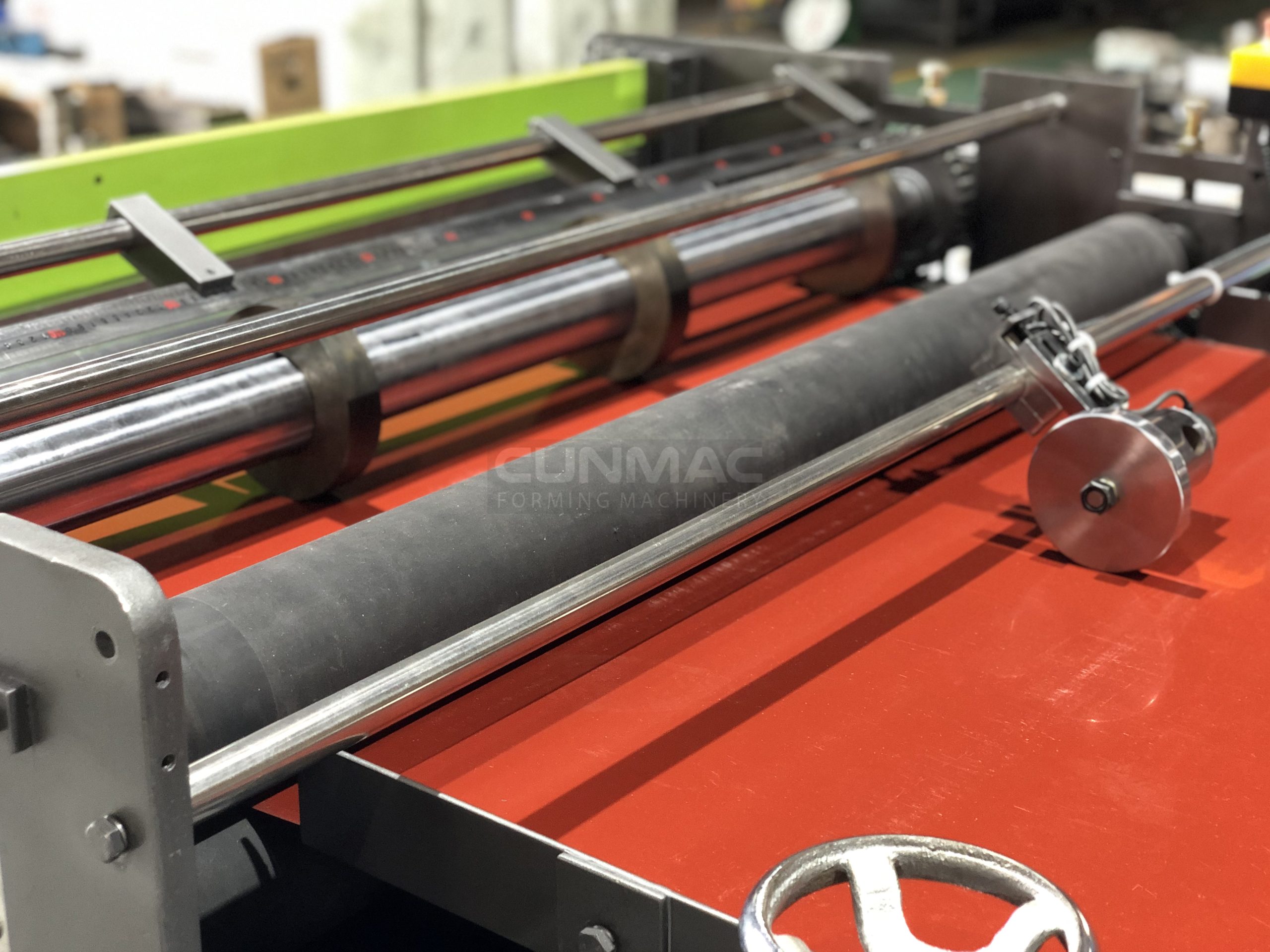

Rubber roller to guide materials in

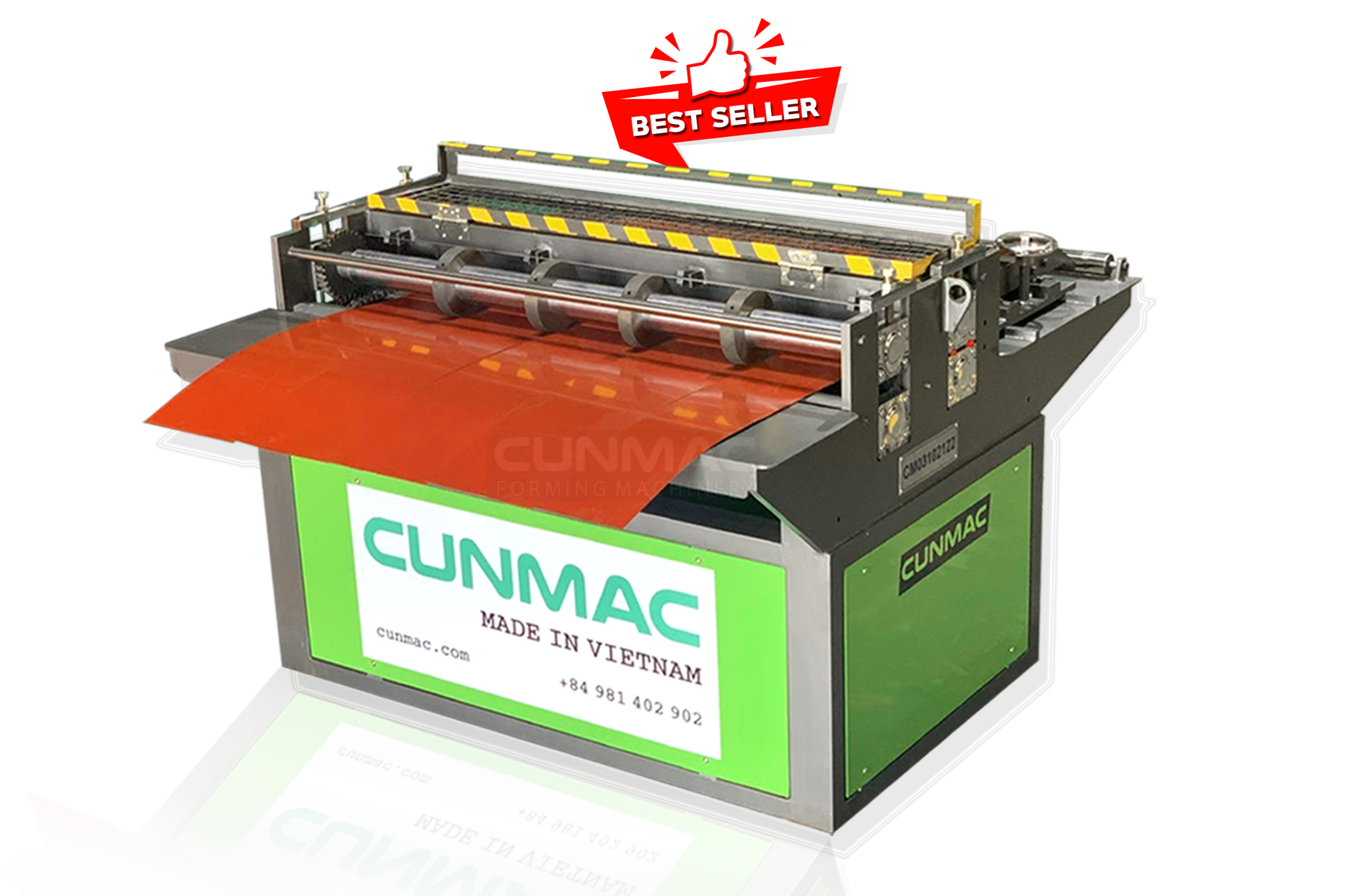

Feeding coil can change the width of coil

Adjustable stripper blade

Automatic programmble length settings via touch panel

Encoder to count the length of materials

Up and down system for quick adjustment